In the realm of baked goods, cookies hold a special place. From classic chocolate chip to exotic flavors, cookies are a favorite treat worldwide. As the demand for cookies continues to rise, so does the need for efficient production methods. This is where cookies making machines come into play. These machines have revolutionized the cookie production process, making it faster, more consistent, and more cost-effective.

Evolution of Cookies Making Machines

The evolution of cookies making machines mirrors the broader trends in food manufacturing. Historically, cookie production was a manual process, involving hand-mixing, shaping, and baking. As bakeries and confectioneries grew in scale, the need for automation became evident. Early cookie machines were relatively simple, designed to streamline the dough mixing and shaping processes.

Over the decades, technological advancements have led to the development of sophisticated cookies making machines. Modern machines incorporate features such as programmable controls, high-capacity mixers, and advanced shaping mechanisms. These innovations have transformed cookie production from a labor-intensive task to a highly automated process, allowing for greater production volumes and consistency.

How Cookies Making Machines Work

Cookies making machines are designed to handle various stages of cookie production, including mixing, shaping, and baking. Here’s a brief overview of how these machines typically work:

Mixing: The process begins with the mixing of ingredients. Cookies making machines are equipped with powerful mixers that can handle large quantities of dough. These mixers ensure that ingredients are thoroughly combined, resulting in a uniform dough.

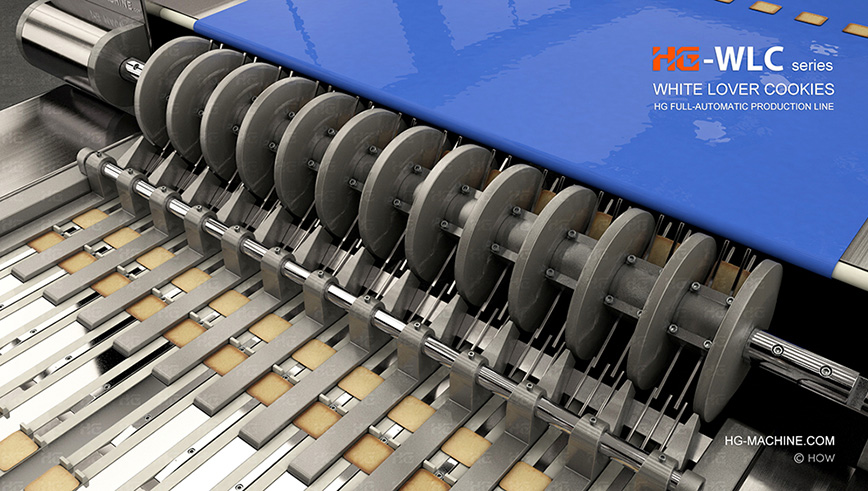

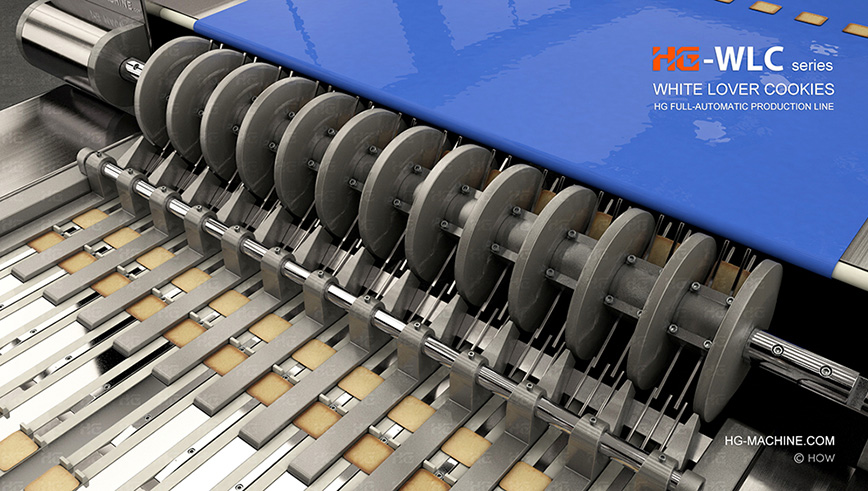

Shaping: Once the dough is mixed, it is transferred to the shaping section of the machine. Modern cookies making machines use various methods for shaping cookies, including rotary die systems and extrusion systems. These mechanisms can produce a wide range of cookie shapes and sizes, from round and oval to intricate designs.

Depositing: After shaping, the cookies are deposited onto baking trays or conveyor belts. Some machines are equipped with automated depositing systems that place the cookies at precise intervals, ensuring even baking.

Baking: The cookies are then baked in ovens that are often integrated into the production line. Advanced baking systems ensure consistent heat distribution, resulting in evenly baked cookies with a perfect texture.

Cooling and Packaging: Once baked, cookies are cooled and packaged. Modern machines may include automated cooling conveyors and packaging systems, further enhancing efficiency.

Benefits of Cookies Making Machines

The adoption of cookies making machines offers several benefits:

Increased Efficiency: Automated machines can produce large quantities of cookies in a fraction of the time it would take manually. This increased efficiency is crucial for meeting high demand and maintaining supply.

Consistency: One of the biggest challenges in cookie production is achieving consistency in size, shape, and texture. Cookies making machines ensure uniformity, reducing the likelihood of defects and ensuring a high-quality product.

Cost-Effectiveness: While the initial investment in cookies making machines can be significant, the long-term savings are considerable. Automation reduces labor costs, minimizes waste, and increases production capacity, leading to lower overall production costs.

Flexibility: Modern cookies making machines are versatile and can handle a variety of cookie recipes and shapes. This flexibility allows manufacturers to experiment with new flavors and designs without significant changes to the production process.

Improved Hygiene: Automated systems reduce the need for manual handling, which minimizes the risk of contamination. This improved hygiene is essential for maintaining high food safety standards.