A Sandwich Cake Production Line is a fully automated system designed for the mass production of sandwich cakes, which are popular for their fluffy texture and rich filling layers. These cakes consist of multiple layers of soft sponge cake filled with a variety of creams, jams, or even fruit fillings. The production line incorporates several machines working in harmony to create perfectly layered cakes with minimal manual intervention.

Key Components of the Sandwich Cake Production Line

Dough Mixing and Batter Preparation: The first stage of the production line involves preparing the cake batter. Advanced mixers ensure the perfect consistency and texture for the sponge cake. Ingredients such as flour, eggs, sugar, and butter are combined precisely, reducing human error and ensuring a consistent base for every cake.

Baking System: The batter is then baked in high-efficiency ovens, often with multiple temperature zones to ensure an even bake. These ovens are designed to handle high volumes of batter while ensuring that each cake layer is baked to perfection, with the right level of softness and moisture content.

Cooling Conveyor: After baking, the cakes are transferred to cooling conveyors, where they are gradually cooled to room temperature. This step is crucial for achieving the right texture and making it easier for the next stages of the production line.

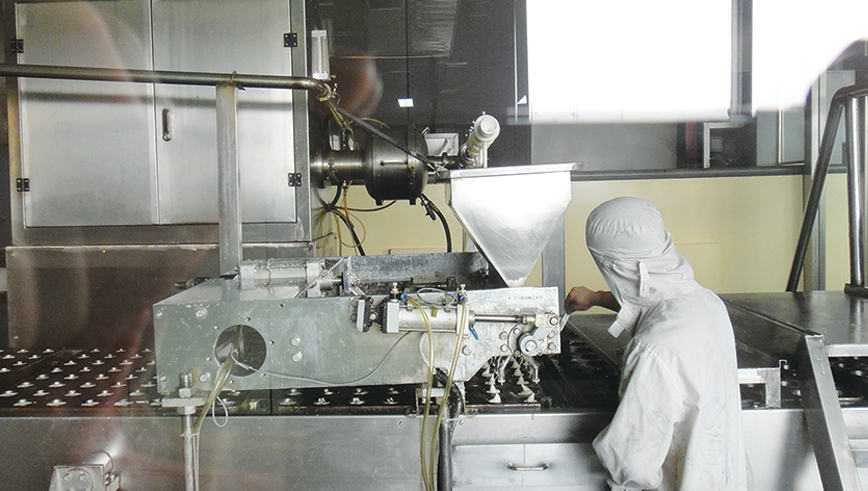

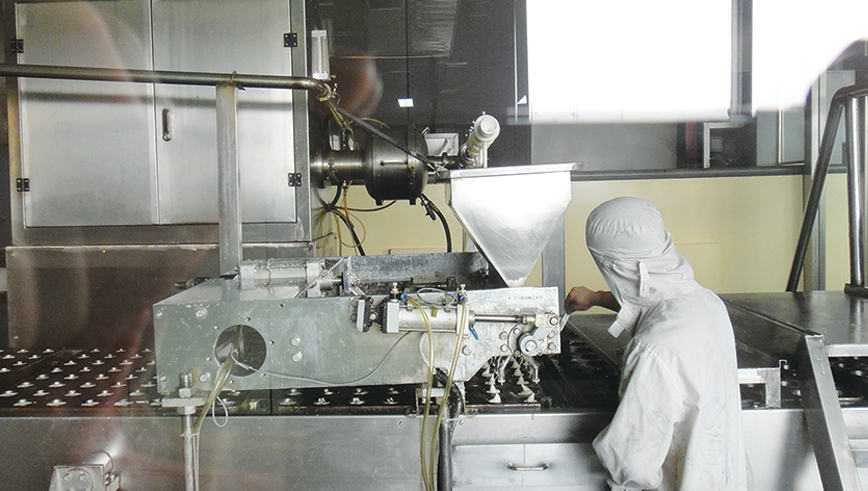

Layering and Filling: The cooled sponge cake layers are then passed through a precise layering system, where a filling is injected between the layers. This can range from a light cream to fruit preserves, depending on the product's intended flavor. The precision of the layering process ensures that each sandwich cake has an equal distribution of filling, resulting in a uniform product.

Cutting and Packaging: Once the cakes are filled, they are cut into uniform sizes by automated cutting machines. The final products are then automatically packaged in protective wrapping or boxes, ensuring that they remain fresh and protected during shipping.

Benefits of Using a Sandwich Cake Production Line

Increased Production Capacity: A major advantage of the Sandwich Cake Production Line is its ability to produce large quantities in a short amount of time. This is particularly valuable for bakeries and manufacturers dealing with high demand, especially during festive seasons or promotional events.

Consistency and Quality: With fully automated processes, the production line minimizes human error, ensuring that every cake is of the same high quality. This consistency in flavor, texture, and appearance is critical in maintaining a strong brand reputation.

Reduced Labor Costs: Automation significantly reduces the need for manual labor, allowing companies to cut down on staffing requirements while improving overall efficiency. This results in lower operational costs and higher profit margins.

Customization: Advanced Sandwich Cake Production Lines offer flexibility in terms of customization. Manufacturers can easily adjust the filling types, cake sizes, and flavors, allowing them to cater to different market demands and customer preferences.